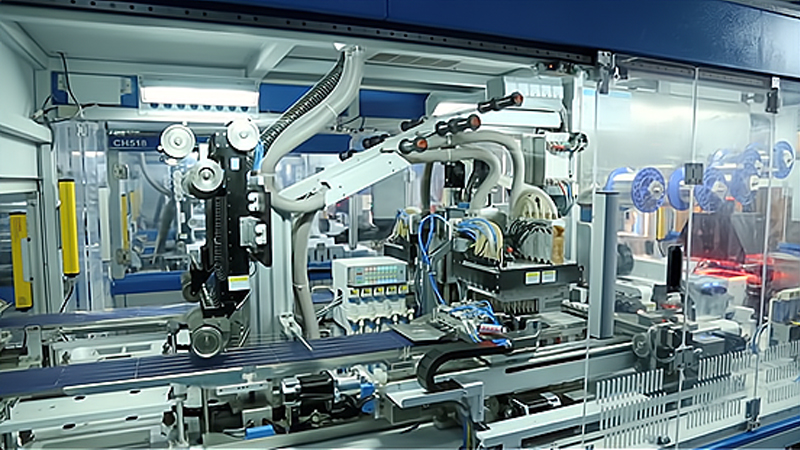

What is the principle of dry ice cleaning?

Dry ice spray cleaning, also known as cold spraying, uses compressed air as the power and carrier, dry ice particles as acceleration particles, and is sprayed onto the surface of the object to be cleaned through a dedicated spray cleaner, where high-speed solid dry ice particles are sprayed onto the surface of the object to be cleaned( Δ Pulse transformation and sublimation of Mv, using energy conversion such as melting, to remove dirt, oil stains, residual impurities, etc. On the surface of the object to be cleaned, it can quickly freeze for condensation, fragility, separation, and can be removed by airflow.

Freeze Peeling

If dry ice particles at 78.5 ℃ act on the surface of the object to be cleaned, first freeze the fragile dirt. Dirt breaks on the surface to be cleaned and changes from a viscoelastic state to a solid. As brittleness increases and viscosity decreases, the adsorption force on the surface sharply decreases. Meanwhile, as the surface increases, some dirt can be automatically removed.

Cleaning and peeling

In environments where compressed air is used for electricity, it generates shear forces on fragile dirt and leads to mechanical fracture. Due to the significant difference in low-temperature shrinkage rate between dirt and clean object surfaces, stress is concentrated on the contact surface, and dirt peels off under shear force.

Impact isolation

When high-speed dry ice particles collide with a raised dirt surface, the aforementioned kinetic energy is transferred to the dirt to overcome the reduced adhesion force. Therefore, the generated shear force will cause dirt to roll away with the airflow, thereby achieving the goal of removing dirt.